AI-Enhanced MEP

AI-Enhanced MEP

Michael Ruhl is the Managing Partner and Head of Engineering at RUHL, bringing more than 30 years of global experience in mechanical design, energy efficiency, and decarbonization. A licensed Professional Engineer with degrees in Mechanical Engineering and Management from the University of Kaiserslautern, Germany, Michael has led projects across sectors including district energy, hospitality, industrial, commercial, and residential.

Recognized as Newcomer of the Year 2022 by the German American Chamber of Commerce in NYC and as a partner in NYSERDA’s Empire Building Challenge, Michael has become a trusted leader in advancing energy-efficient, carbon-neutral solutions worldwide. His portfolio spans projects from district heating stations in China to carbon-neutral hotels and large-scale residential and commercial developments in Europe and the U.S.

Driven by a passion for eliminating fossil fuels and advancing renewable energy, Michael applies decades of engineering expertise and global perspective to deliver innovative, high-performance solutions. His proven record in decarbonization and system integration positions him as a global leader in transforming the built environment for a Net Zero future.

Evaluating existing building HVAC systems involves assessing their performance, efficiency, and functionality to identify inefficiencies and opportunities for improvement. The process helps optimize energy use, comfort, and cost savings while meeting sustainability goals.

An equipment schedule outlines the specifications, locations, and quantities of all equipment within a building or project. It ensures proper planning, coordination, and tracking of equipment for efficient installation and operation.

The Utility Analysis will be developed based on existing energy bills to understand as-built performance of the building and calibrate the thermal building simulation results.

Only “Energy Efficiency First” makes renewable supply feasible by reducing the overall energy loads, downsizing equipment and reducing investment and operation cost.

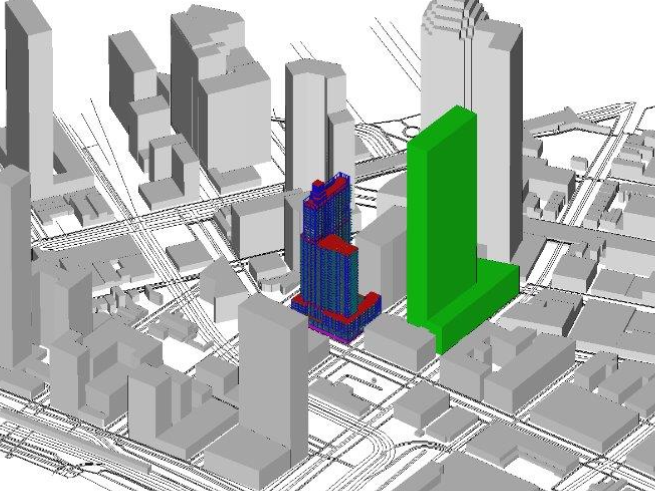

The 3D-Model will be built based on architectural design (incl. wall structure, u-values etc.) together with the surrounding high rises as precondition for a thermal simulation under realistic conditions.

Creating a 3D model of the mechanical room involves designing a digital representation of the space, including equipment, systems, and layout. This model aids in spatial planning, coordination, and identifying potential design conflicts.

On-site measurements involve collecting data on U-values of windows, façades, roofs, and interiors, as well as performing ultra-sonic flow measurements. These measurements help assess energy efficiency and system performance for accurate building analysis and optimization.

Thermal building simulation involves creating a digital model to analyze a building’s thermal performance, including heat flow, insulation, and energy use. It helps optimize energy efficiency, comfort, and sustainability by predicting how the building will respond to different environmental conditions.

The design work will be based on thermal building simulation, energy modeling and Pipe Flow Simulation.

The Energy Modeling is to optimize the dimensioning of the equipment for heat/cooling generation, storage and supply.

Evaluation of Energy Savings play a vital role in the development of Decarb Projects and Economic Feasibility. Local and federal regulations, ESG strategies and other relevant drivers are focusing on carbon emissions reduction.

Every conception must pass an Economical Assessment by proving to be the most efficient approach in terms of capital expenditure and operational expenses.